NO SETUP FEES

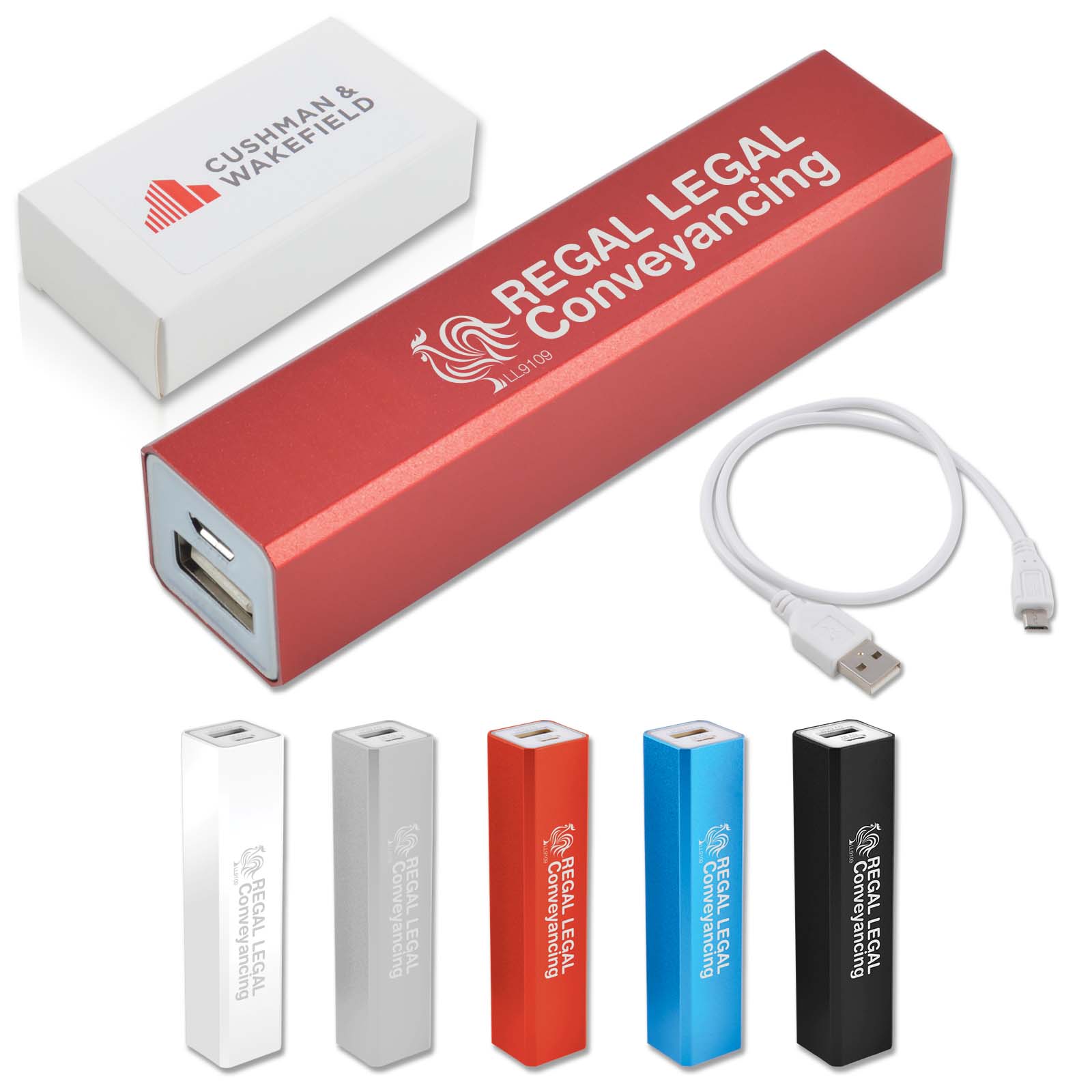

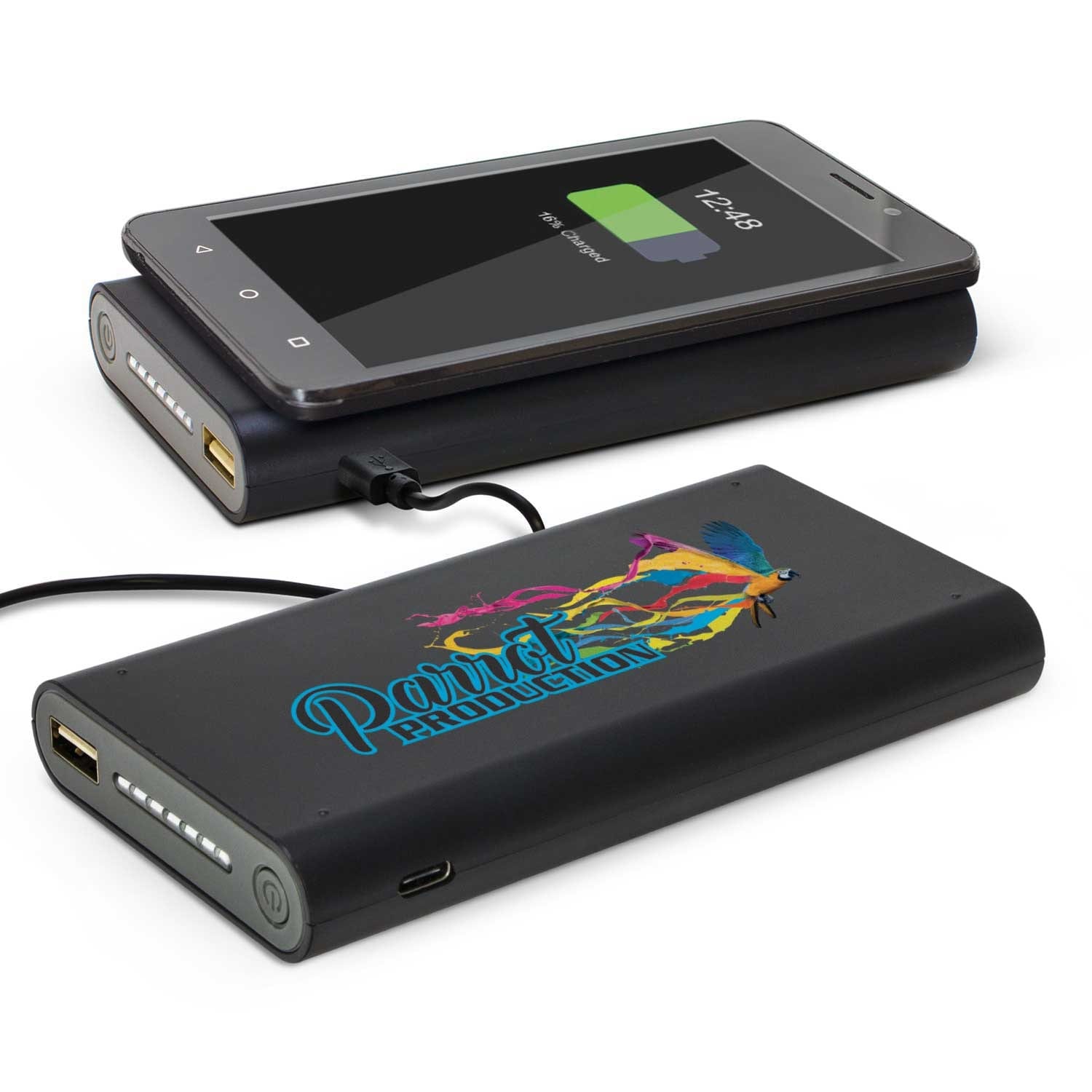

Custom Branded Power Banks

Custom branded power banks are a powerful way to promote your business while offering real everyday value. Personalised power banks are highly sought-after promotional products, helping keep your brand visible whenever devices need charging, whether at work, events, or on the go.

Express Promo offers a wide range of customisable power banks, including torch power banks and charging stations, to suit your brand and budget. These promotional items are ideal for staff gifts, client onboarding packs, business meetings, and corporate events, delivering strong brand impact without a large marketing spend.

Express Promo is leading the industry in custom branded promotional products with unbeatable lead times. A massive range with a rapid 3-business-day production from artwork approval and payment. We also offer free setup and free delivery Australia-wide, with friendly support from product selection through to final dispatch.

EXPRESS OFFERS

EXPRESS OFFERS

Colourflex transfers are a CMYK+W digital print process, used for branding apparel and fabrics.

Colourflex transfers are a CMYK+W digital print process, used for branding apparel and fabrics. Direct to product digital printing involves the transfer of ink directly from the print heads of an inkjet machine to the product and can be used to produce both spot colour and full colour branding on flat or slightly curved surfaces.

Direct to product digital printing involves the transfer of ink directly from the print heads of an inkjet machine to the product and can be used to produce both spot colour and full colour branding on flat or slightly curved surfaces. Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

Resin coated finish is produced by printing the artwork onto a vinyl material with strong adhesive on the reverse. The branded area is coated with a crystal clear resin which is allowed to dry. Once dry, the finished decal is applied to the product and the adhesive forms a permanent bond.

Resin coated finish is produced by printing the artwork onto a vinyl material with strong adhesive on the reverse. The branded area is coated with a crystal clear resin which is allowed to dry. Once dry, the finished decal is applied to the product and the adhesive forms a permanent bond. Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

This production method is used for printing media such as paper, vinyl and magnetic material used in the manufacture of labels, badges and fridge magnets etc.

This production method is used for printing media such as paper, vinyl and magnetic material used in the manufacture of labels, badges and fridge magnets etc.

Direct to product rotary digital printing involves the transfer of UV ink directly from inkjet print heads and can be used to produce both spot colour and full colour branding.

Direct to product rotary digital printing involves the transfer of UV ink directly from inkjet print heads and can be used to produce both spot colour and full colour branding. Debossing is produced by pressing a hot engraved metal plate into the surface of a product with a lot of pressure. This produces a permanent image below the surface of the product. Some products offer thermo debossing, which creates a stunning two-tone finish.

Debossing is produced by pressing a hot engraved metal plate into the surface of a product with a lot of pressure. This produces a permanent image below the surface of the product. Some products offer thermo debossing, which creates a stunning two-tone finish. Sublimation print is used for branding products that have a special coating on them or fabrics suitable for the sublimation process. A transfer is produced by printing sublimation ink onto transfer paper and then heat pressing it onto the product.

Sublimation print is used for branding products that have a special coating on them or fabrics suitable for the sublimation process. A transfer is produced by printing sublimation ink onto transfer paper and then heat pressing it onto the product. Imitation etch is a special pad printing ink used for producing an etch like effect on glass products.

Imitation etch is a special pad printing ink used for producing an etch like effect on glass products. Pad printing uses a silicone pad to transfer an image to a product from a laser etched printing plate. It is one of the most popular and affordable ways of branding promotional products due to its ability to reproduce images on uneven or curved products and print multiple colours in a single pass.

Pad printing uses a silicone pad to transfer an image to a product from a laser etched printing plate. It is one of the most popular and affordable ways of branding promotional products due to its ability to reproduce images on uneven or curved products and print multiple colours in a single pass.