Look no further! Express Promo may be seeking enthusiastic individuals to join our dynamic team.

If you are interested in joining our team please get in touch by completing the form below.

*Be sure to upload a copy of your resume and complete the steps below.

If we think you are suitable you will be first in line for us to contact when we have openings become available.

Perks and Benefits

- Join a close-knit team with great culture (we celebrate birthdays with cake!)

- Fun-filled team-building activities and outings

- The opportunity to let your creativity run wild and see your ideas come to life

- Room for growth, development and training – we love to see our team members shine!

- Hybrid and part-time hours will be negotiable for the right candidate.

- Ready to embark on an exciting journey with Express Promo? Show us your personality and tell us why you’re the perfect fit for our team in your cover letter!

Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects. Imitation etch is a special pad printing ink used for producing an etch like effect on glass products.

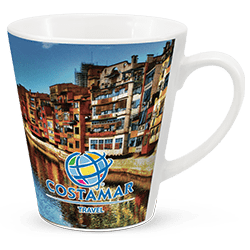

Imitation etch is a special pad printing ink used for producing an etch like effect on glass products. Sublimation print is used for branding products that have a special coating on them or fabrics suitable for the sublimation process. A transfer is produced by printing sublimation ink onto transfer paper and then heat pressing it onto the product.

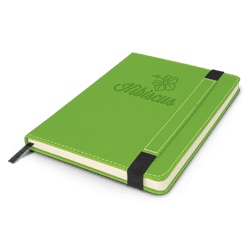

Sublimation print is used for branding products that have a special coating on them or fabrics suitable for the sublimation process. A transfer is produced by printing sublimation ink onto transfer paper and then heat pressing it onto the product. Debossing is produced by pressing a hot engraved metal plate into the surface of a product with a lot of pressure. This produces a permanent image below the surface of the product. Some products offer thermo debossing, which creates a stunning two-tone finish.

Debossing is produced by pressing a hot engraved metal plate into the surface of a product with a lot of pressure. This produces a permanent image below the surface of the product. Some products offer thermo debossing, which creates a stunning two-tone finish. Direct to product rotary digital printing involves the transfer of UV ink directly from inkjet print heads and can be used to produce both spot colour and full colour branding.

Direct to product rotary digital printing involves the transfer of UV ink directly from inkjet print heads and can be used to produce both spot colour and full colour branding.

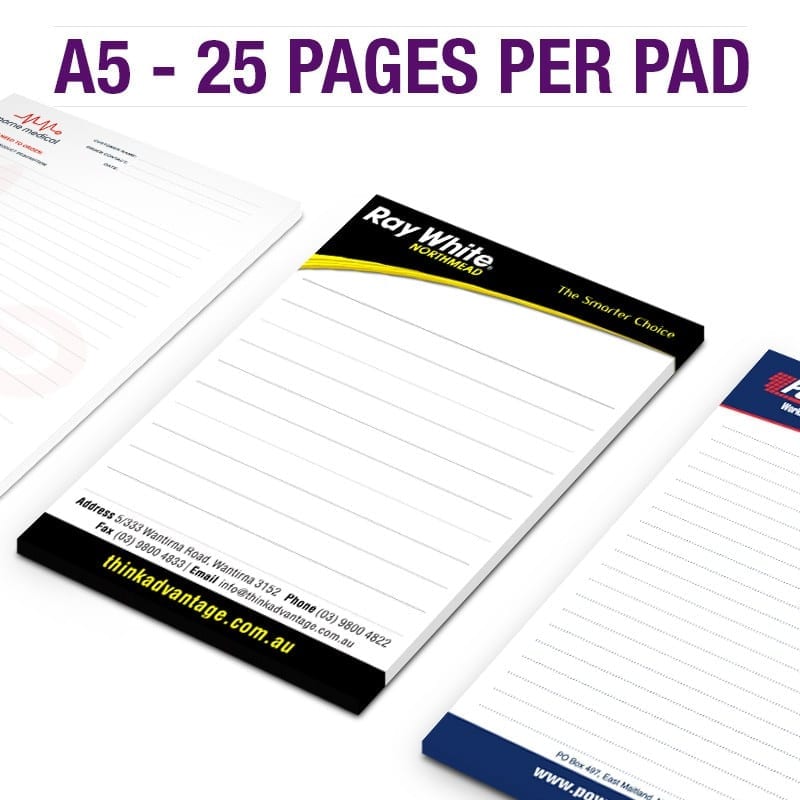

This production method is used for printing media such as paper, vinyl and magnetic material used in the manufacture of labels, badges and fridge magnets etc.

This production method is used for printing media such as paper, vinyl and magnetic material used in the manufacture of labels, badges and fridge magnets etc.

Resin coated finish is produced by printing the artwork onto a vinyl material with strong adhesive on the reverse. The branded area is coated with a crystal clear resin which is allowed to dry. Once dry, the finished decal is applied to the product and the adhesive forms a permanent bond.

Resin coated finish is produced by printing the artwork onto a vinyl material with strong adhesive on the reverse. The branded area is coated with a crystal clear resin which is allowed to dry. Once dry, the finished decal is applied to the product and the adhesive forms a permanent bond.

Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects. Direct to product digital printing involves the transfer of ink directly from the print heads of an inkjet machine to the product and can be used to produce both spot colour and full colour branding on flat or slightly curved surfaces.

Direct to product digital printing involves the transfer of ink directly from the print heads of an inkjet machine to the product and can be used to produce both spot colour and full colour branding on flat or slightly curved surfaces. Colourflex transfers are a CMYK+W digital print process, used for branding apparel and fabrics.

Colourflex transfers are a CMYK+W digital print process, used for branding apparel and fabrics. Digital transfers are used for branding fabrics and are printed on transfer paper using a digital printing machine then heat pressed onto the product.

Digital transfers are used for branding fabrics and are printed on transfer paper using a digital printing machine then heat pressed onto the product.