NO SETUP FEES

Our Commitments

Express Promo company values guide the manner in which we conduct business and this includes being ‘Above The Line’ and taking responsibility for our actions and business impact. We make a commitment to all our stakeholders – including employees, customers, suppliers, business partners, community and the environment, to conduct our business ethically. The below information details the commitments we make and how we ensure we uphold them.

For any additional information or if you have any questions, please do not hesitate to contact our Compliance Manager at [email protected].

Our dedication lies in safeguarding our planet’s ecosystems, and we actively integrate sustainability principles into our operations. Our efforts include:

- Minimising our consumption of natural resources and energy

- Reducing waste generation

- Lowering Co2 emissions and continuously tracking these emissions

- Enhancing the awareness and understanding of Express Promos’ sustainability efforts and achievements among our stakeholders

Regarding Greenwashing:

Greenwashing involves exaggerated or unfounded claims about a product’s or service’s environmental advantages. Express Promo pledges to adhere to responsible environmental practices that produce real benefits. We commit to avoiding inflated or misleading statements about our products’ environmental advantages. Our promotion and communication strategies will follow Government regulations, ensuring an honest and accurate portrayal of our environmental impact.

Concerning ACCC Guidelines, NZ Commerce Commission Guidelines, and Forest Stewardship Council (FSC) Certification:

Forest Stewardship Council (FSC) Certification:

The FSC is an autonomous entity dedicated to the preservation of robust and resilient forests. Their certification sets standards for forestry practices that are environmentally sound, socially advantageous, and economically feasible.

Whenever feasible, we opt for products accredited by the FSC. In situations where FSC certification is not available, we require our suppliers to offer traceability details for raw materials to eliminate risks associated with unlawful logging.

We ensure that items in our range are safe & compliant to all regulations in the markets in which it is sold.

We achieve this through a system of proactive management of product quality and safety:

- Dedicated resource for Product Safety and Compliance, responsible for overseeing our end-end product safety processes

- Maintain internal knowledge of safety standards, regulations and guidelines to ensure we can proactively audit and review product against these criteria

- Mandatory pre-introduction risk assessment and implementation of a product safety action plan appropriate to the nature of the product and any associated risks. Where appropriate, this may include:

- External product safety testing by verified third parties

- Product quality testing and inspections to ensure the product functions as intended.

- Appropriate packaging and labelling

- Ongoing review and maintenance

- Monitoring changes in regulations and standards and implementing action plans to ensure ongoing compliance

Express Promo ensures ethical undertakings through the implementation and communication of a Business ethics policy that covers:

- Trust and Credibility

- Open and Honest Communication

- Upholding the Law

- Identification and Management of Conflicts of Interest

- Acceptance of Business Courtesies

- Travel and Accomodation

- Offering of Business Courtesies and Gifts

- Confidential and Proprietary Information

EXPRESS OFFERS

EXPRESS OFFERS

Colourflex transfers are a CMYK+W digital print process, used for branding apparel and fabrics.

Colourflex transfers are a CMYK+W digital print process, used for branding apparel and fabrics. Direct to product digital printing involves the transfer of ink directly from the print heads of an inkjet machine to the product and can be used to produce both spot colour and full colour branding on flat or slightly curved surfaces.

Direct to product digital printing involves the transfer of ink directly from the print heads of an inkjet machine to the product and can be used to produce both spot colour and full colour branding on flat or slightly curved surfaces. Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

Resin coated finish is produced by printing the artwork onto a vinyl material with strong adhesive on the reverse. The branded area is coated with a crystal clear resin which is allowed to dry. Once dry, the finished decal is applied to the product and the adhesive forms a permanent bond.

Resin coated finish is produced by printing the artwork onto a vinyl material with strong adhesive on the reverse. The branded area is coated with a crystal clear resin which is allowed to dry. Once dry, the finished decal is applied to the product and the adhesive forms a permanent bond. Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

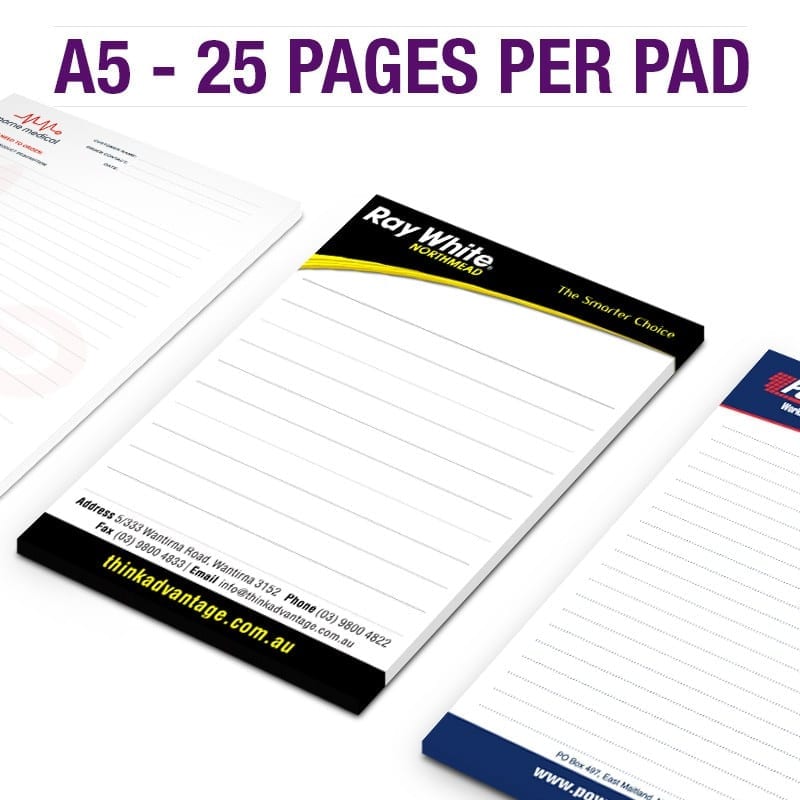

This production method is used for printing media such as paper, vinyl and magnetic material used in the manufacture of labels, badges and fridge magnets etc.

This production method is used for printing media such as paper, vinyl and magnetic material used in the manufacture of labels, badges and fridge magnets etc.

Direct to product rotary digital printing involves the transfer of UV ink directly from inkjet print heads and can be used to produce both spot colour and full colour branding.

Direct to product rotary digital printing involves the transfer of UV ink directly from inkjet print heads and can be used to produce both spot colour and full colour branding. Debossing is produced by pressing a hot engraved metal plate into the surface of a product with a lot of pressure. This produces a permanent image below the surface of the product. Some products offer thermo debossing, which creates a stunning two-tone finish.

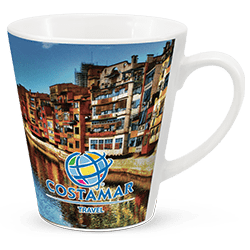

Debossing is produced by pressing a hot engraved metal plate into the surface of a product with a lot of pressure. This produces a permanent image below the surface of the product. Some products offer thermo debossing, which creates a stunning two-tone finish. Sublimation print is used for branding products that have a special coating on them or fabrics suitable for the sublimation process. A transfer is produced by printing sublimation ink onto transfer paper and then heat pressing it onto the product.

Sublimation print is used for branding products that have a special coating on them or fabrics suitable for the sublimation process. A transfer is produced by printing sublimation ink onto transfer paper and then heat pressing it onto the product. Imitation etch is a special pad printing ink used for producing an etch like effect on glass products.

Imitation etch is a special pad printing ink used for producing an etch like effect on glass products. Pad printing uses a silicone pad to transfer an image to a product from a laser etched printing plate. It is one of the most popular and affordable ways of branding promotional products due to its ability to reproduce images on uneven or curved products and print multiple colours in a single pass.

Pad printing uses a silicone pad to transfer an image to a product from a laser etched printing plate. It is one of the most popular and affordable ways of branding promotional products due to its ability to reproduce images on uneven or curved products and print multiple colours in a single pass.